12th Annual European Electric Steelmaking Conference

Written by John Lewis, EngD student in the Materials and Manufacturing Academy, Swansea University

The 12th Annual European Electric Steelmaking Conference was a prestigious event held at an equally prestigious facility, at the University of Sheffield. A city with a heritage built on Steel, was quite a fitting environment to engage and hear from the leading experts in the field of Electric Steelmaking on the latest advancements and challenges. The conference focused primarily on five principal technology based themes including Process, Environment & Society, Plant, Energy and Industry 4.0. Steelmakers and representatives from the supporting sectors for the industry, came together over the two days to tackle some of the largest issues facing the European Steel Industry. It was evident from the many talks and discussions, that in order to survive and develop in a competitive market, the challenges of sustainability and responsibility as steelmakers are paramount. We are faced with the challenge to increase the output of high quality and diverse products to the market, while ensuring we minimise our carbon footprint, working towards the net zero carbon objective.

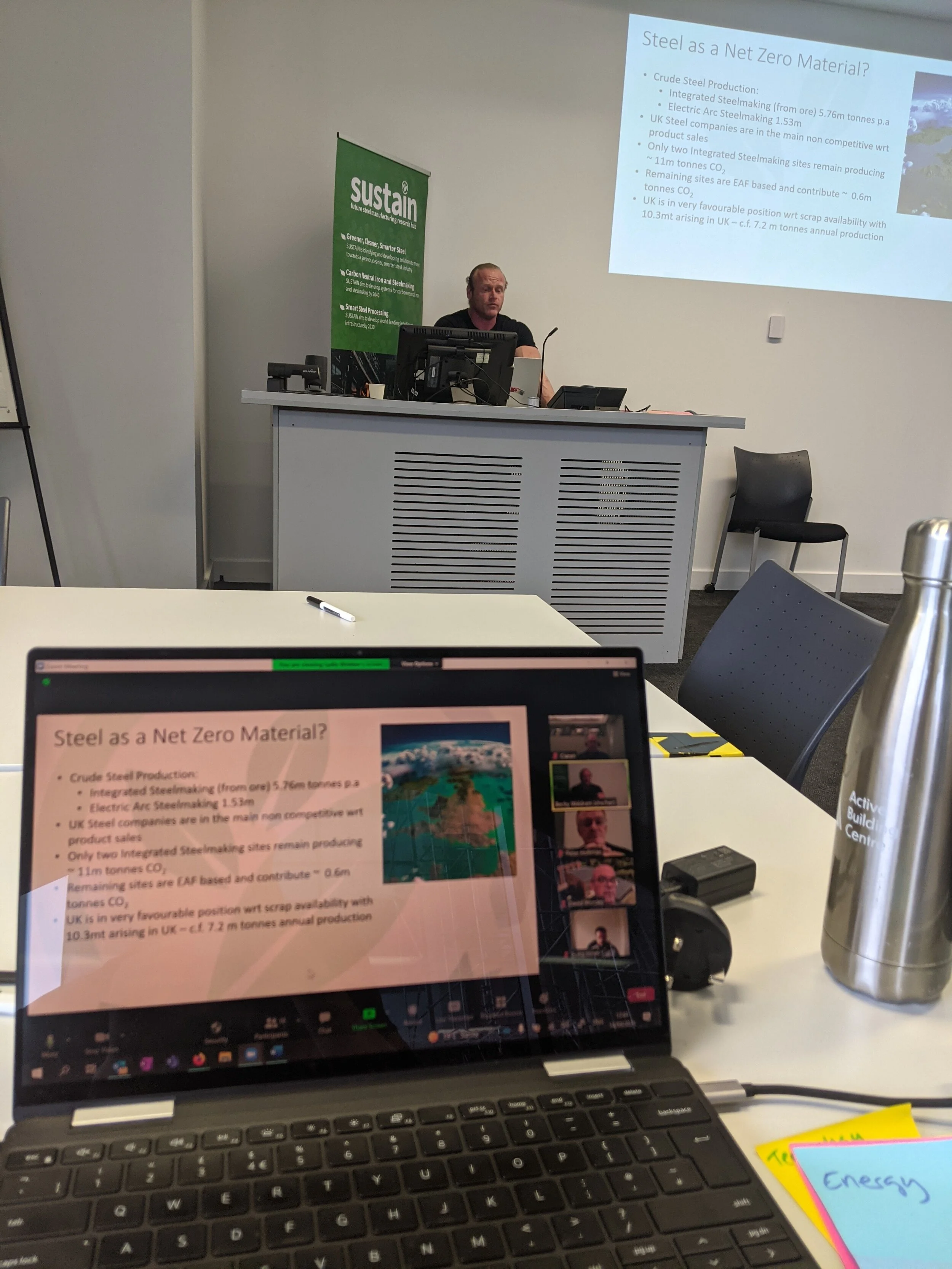

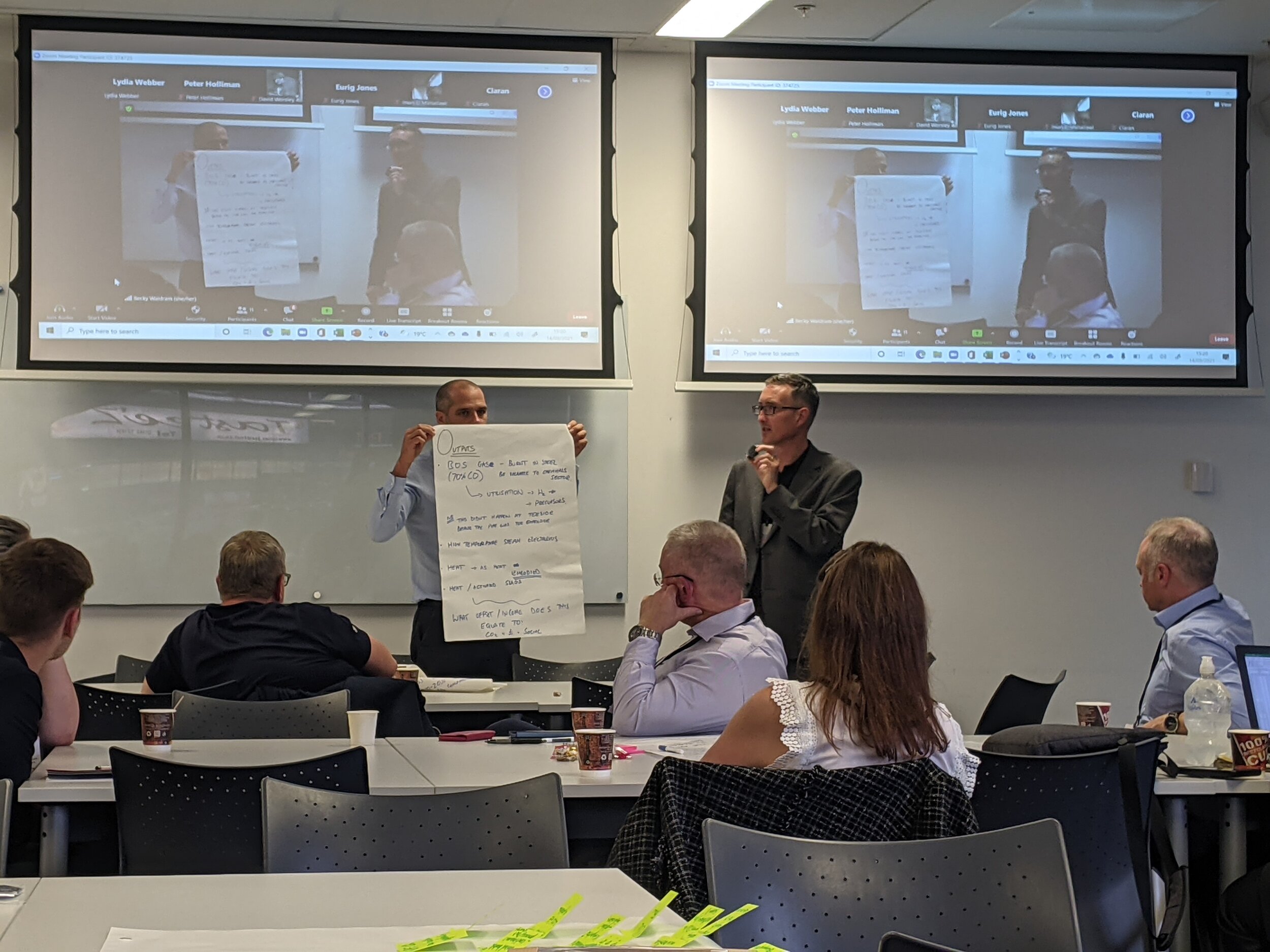

This year the conference took on a hybrid form, where delegates had the choice to attend virtually or in person and presenters could deliver their content virtually also, if they were unable to attend, making the best use of the technology available to us, adapting in these somewhat strange times. After the opening of the conference by the Organisation Committee Chair Bob Ruddlestone, the conference themes flowed nicely into each other. The sustainability challenge was addressed in one of the three lecture halls, while industry 4.0 advancements in technology and metallurgy were being discussed in the others initially. Experts from a range of backgrounds both academic and industrial gave talks ranging from introducing augmented reality for training programs in the workplace to the upscaling of renewable energy for powering the steelplants of the future. The pace of the conference was fast and flowing, which gave a real sense of the direction of the industry itself. Following on from the high standards of the previous day, day two consisted of talks from the industrial experts on what brand new technologies were available to use in the steel industry and conversations on how to prepare for the electrification of the steel industry. The topics appeared to align themselves well with the key challenges that the industry is currently facing.

Day two and towards the final parts of the conference, SUSTAIN a gold sponsor of the event, held a workshop on “The Steelplant of the Future: How to Achieve Net Zero”, developing a pathway to decarbonisation. This workshop began with SUSTAIN’s Programme Manager, Dr. Richard Curry, providing some balance and relevance to the topics discussed previously within the conference and demonstrated what SUSTAIN had been working on to push the industry into the future of green steel manufacturing. Within this workshop delegates chose to discuss and feedback on key challenging areas that electric steelmakers face, to gather ideas and help solve the problems we face. I attended the Raw Materials table where the discussion ranged from, out of the box alternatives to the current selection of raw materials we use, to how we can improve the circularity of the product we produce. Other groups fed back on technological requirements and advancements, Renewable Energy and Process Improvements. I think all of the delegates would agree that this was an opportunity for industries to come together to share ideas which they may not have ordinarily heard otherwise.

My conference experience was completed with a visit to the Materials Processing Institute in Middlesbrough, where they were keen to show how they can best support the industry to achieve their aspirations of net zero. With groundbreaking equipment described as the best available in its class. The researchers with a wealth of experience in steelmaking support in issues that arise within steel manufacturing processes and help deliver technological advancements into the industry directly. They work alongside the industry to provide them with thorough investigations and the means to implement new technologies to achieve targets that they wouldn’t necessarily have the resource to achieve internally. Both the knowledge and the equipment available at MPI means that they remain a key driver in the ever changing industry that is steel manufacturing

Overall my experience of this conference has been fantastic and it is clear that there are some huge benefits to attending an event like this. In order to tackle the enormous challenge of achieving net zero, we must come together as an industry and this was certainly the forum to do it!