Our Grand Challenges

GCRA1 - Carbon Neutral Iron and Steelmaking

Carbon Neutrality & Innovative Steelmaking

Steel is ubiquitous in the modern developed world; its low cost and the highly developed industry that produces it enable the standard of living we are accustomed to. From packaging to construction, transport and energy steel plays a major part in our daily lives without notice. Although the steelmaking process is highly efficient, for every tonne of steel produced, twice the amount of CO2 is liberated from fossil fuels to drive the process and its energy requirements. The first of SUSTAIN’s Grand Challenges aims to develop innovative methods to eliminate the carbon footprint of the steelmaking processes and provide a sustainable method of production for a carbon neutral industry which supports global needs.

GCRA2 - Smart Steel Processing

Metrology, Corrosion, Big Data, Industry 4.0 & Alloy Processing

This Grand Challenge aims to revolutionise the steel industry through the development of steels with enhanced mechanical and physical properties, develop increased functionality and utilise the recent developments in sensor technology and digital systems. Focussing on production and supply chains, the Smart Steel Processing Grand Challenge is introducing concepts such as blockchain and tracking technologies into a mature supply chain and customer base that will explicitly describe the manufacturing process and sourced materials on a product by product basis giving the end customer and government bodies full confidence in the products performance, ethical raw material sourcing, production and carbon footprint.

How does SUSTAIN plan to address these challenges?

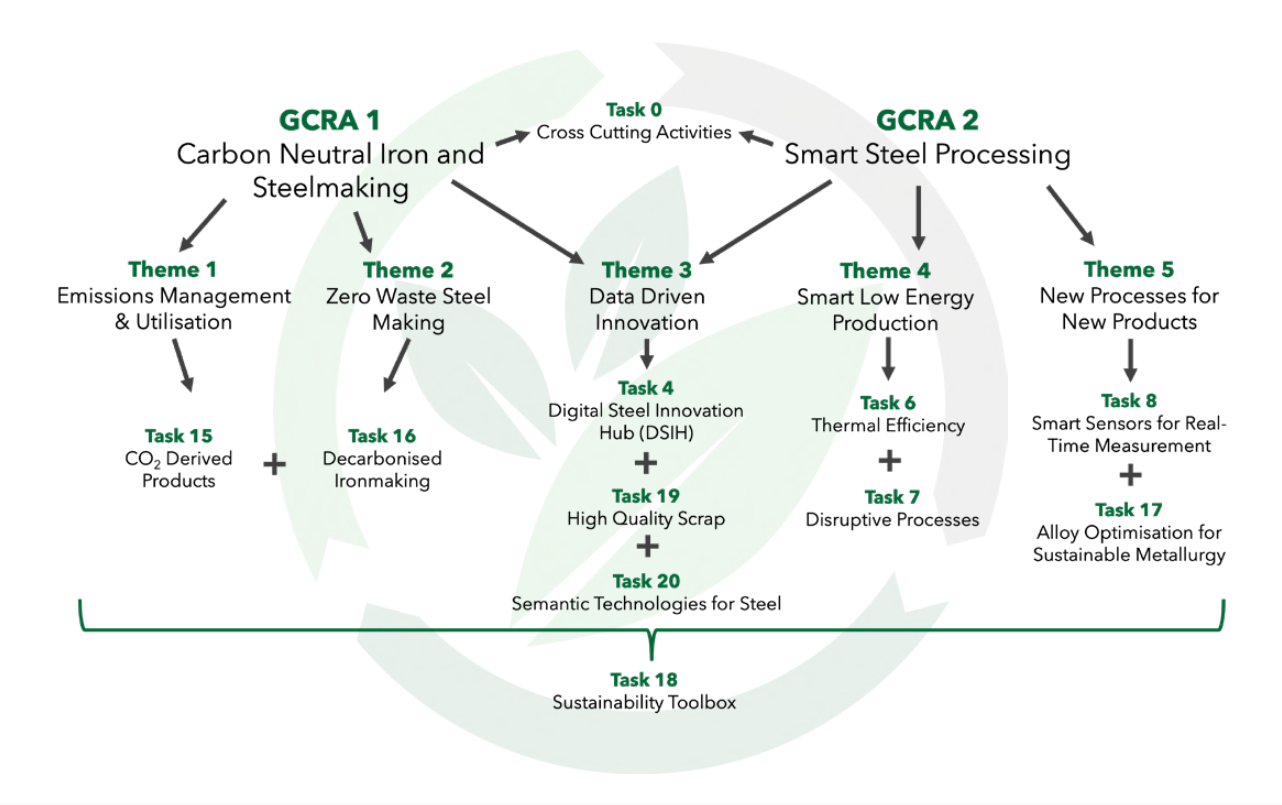

These two Grand Challenges are further divided into five Themes:

Theme 1 - Emissions Management and Utilisation

Theme 2 - Zero Waste Steelmaking

Theme 3 - Data Driven Innovation

Theme 4 - Smart Low Energy Production

Theme 5 - New Processes for New Products

Each Theme contains related research Tasks which are currently under investigation. An example of how our Grand Challenges, Themes and Tasks link together is shown in the diagram below.