SteelSIM 2023

By Ajitesh Sharma – PhD candidate in Warwick Manufacturing Group (WMG), University of Warwick

SteelSIM 2023 was the 10th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, hosted by the WMG within the University of Warwick, in the heart of England on the outskirts of vibrant Coventry. Warwick Manufacturing Group (WMG) was established by Professor Lord Bhattacharyya in 1980 to ignite UK manufacturing in the Steels sector, making the University of Warwick the perfect location to host such a prestigious event.

The scope of the conference was well defined and aimed to bring experts from both industry and academia together to share knowledge and scientific advancements in the areas of ironmaking and steelmaking and also to dive into common challenges and potential solutions for future prospects and developments. Through the course of three days, the programme aimed to tackle a variety of themes; from primary and secondary steelmaking, casting and solidification to machine learning. A vast number of talks were on offer over three parallel speaker sessions for delegates to choose from – each as exhilarating and informative as the other.

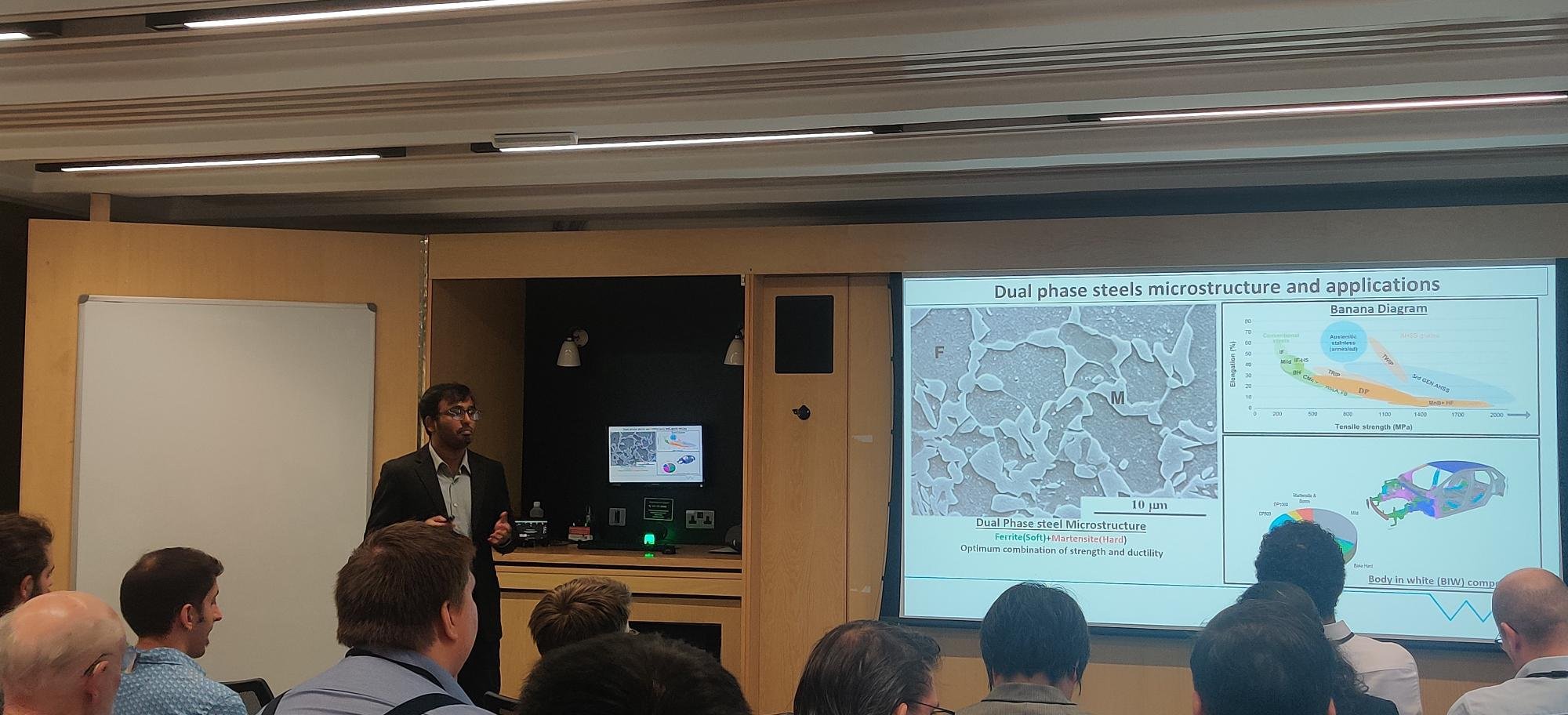

The welcome address kicked off with Professor Claire Davis, head of the Advanced Steel Research Centre at WMG, giving an overview of the days to follow. Claire’s rousing address highlighted to delegates the transformative period we are in to be working within the steel community, which is contributing to low energy solutions, data management and predictive simulation modelling in steel design. This warm welcome ensured a smooth flow into the talks in the three lecture halls. The audience and speakers engaged in every talk giving an ambience of calm and pace to the free-flowing conversations. On the very first day itself, I had given my talk, being the last speaker of day one. I got this fantastic opportunity to present my work and it was a pleasure that my first conference was at the University I’m currently working in. I was thrilled to see many people come up to me after my talk to know more and show genuine interest with technical questions about my experimental procedures and results thus far. Coming together to have informative open discussions at such conferences gives me great joy. The close of day one saw most delegates wanting to see University of Warwick, WMG research facilities, from the Vacuum Induction Melting furnace (VIM) in the hot works area, to the Scanning Electron Microscopes (SEM) and advanced characterisation equipment. Lots of interest was garnered in the facilities and sparked conversations which prompted a second round of tours scheduled on the final day.

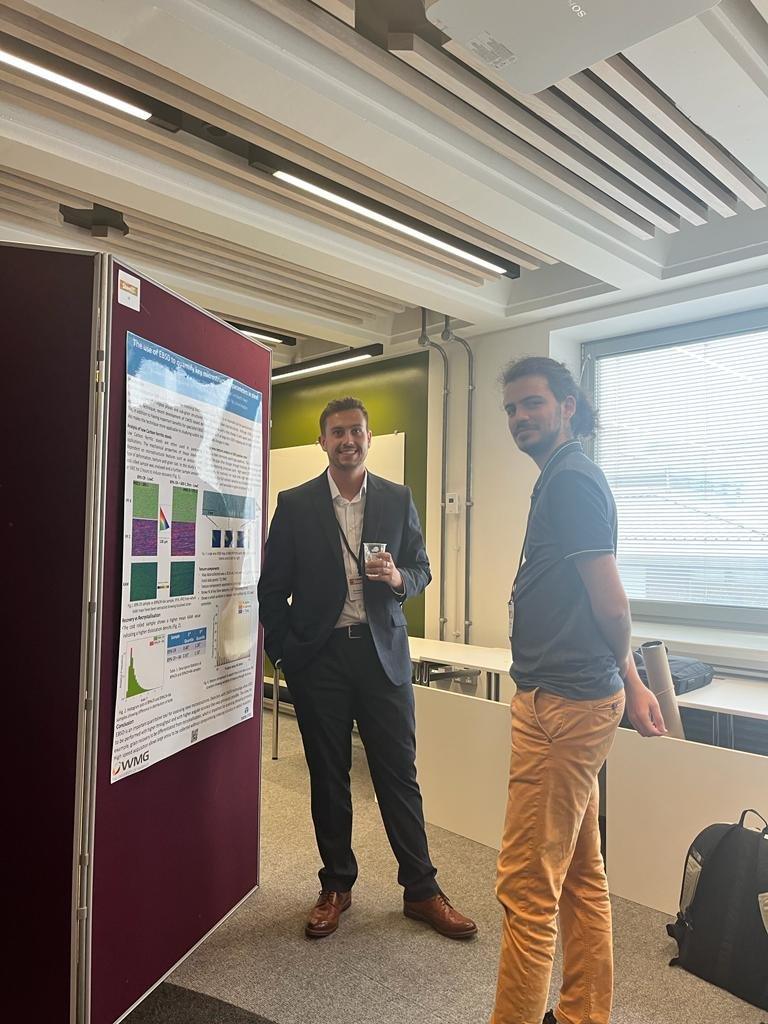

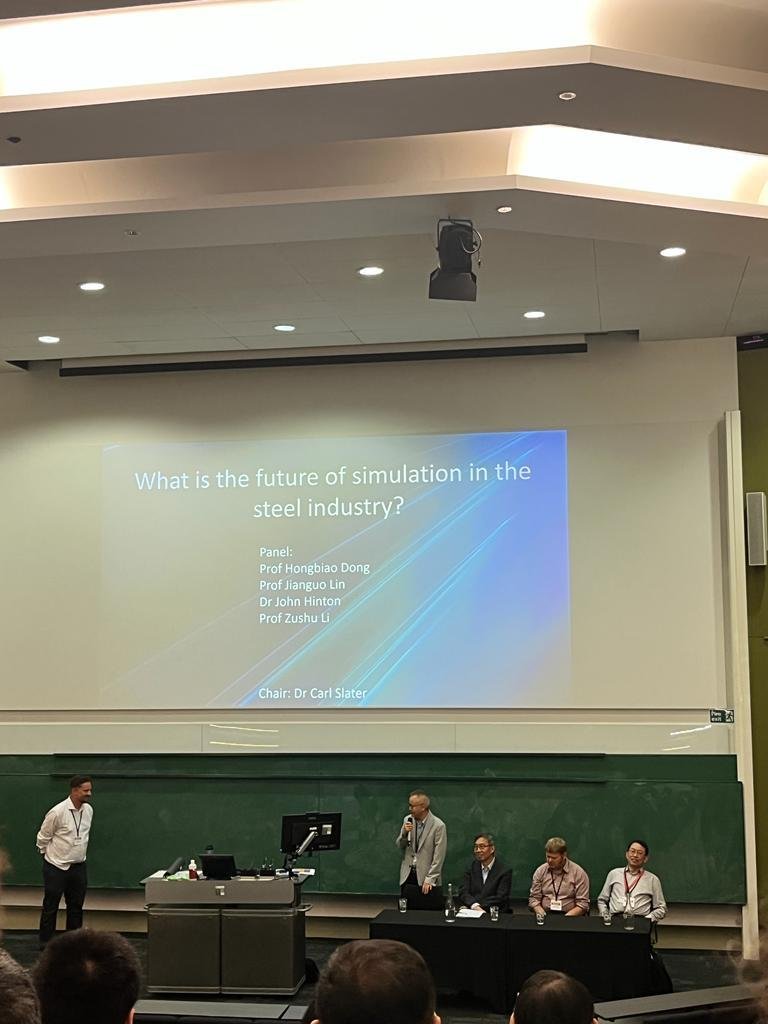

Day two began where the first was concluded; three simultaneous streams of presentations aligned perfectly with key challenges industry is currently facing. This was followed by an all-hands panel session “The Future of Simulation in the Steel Industry”, involving experts in the field to discuss growing demands, challenges and key areas of focus. The audience was able to ask questions and trigger further discussions leading to more thoughts and conversations in the lunch time and break sessions. SUSTAIN was the sponsor of the early career/poster session held giving the audience a chance to wander and network with the wider community while discussing ideas and techniques used for respective work. Day two ended with a splendid dinner at the prestigious Coombe Abbey. Coombe Abbey is most notably famous for its beauty and witnessing some significant moments in history – housing royals and being one of the largest and most influential monasteries in Warwickshire. With the historic site and a backdrop of the sunset it was fitting to host a renowned dinner at this tremendous venue.

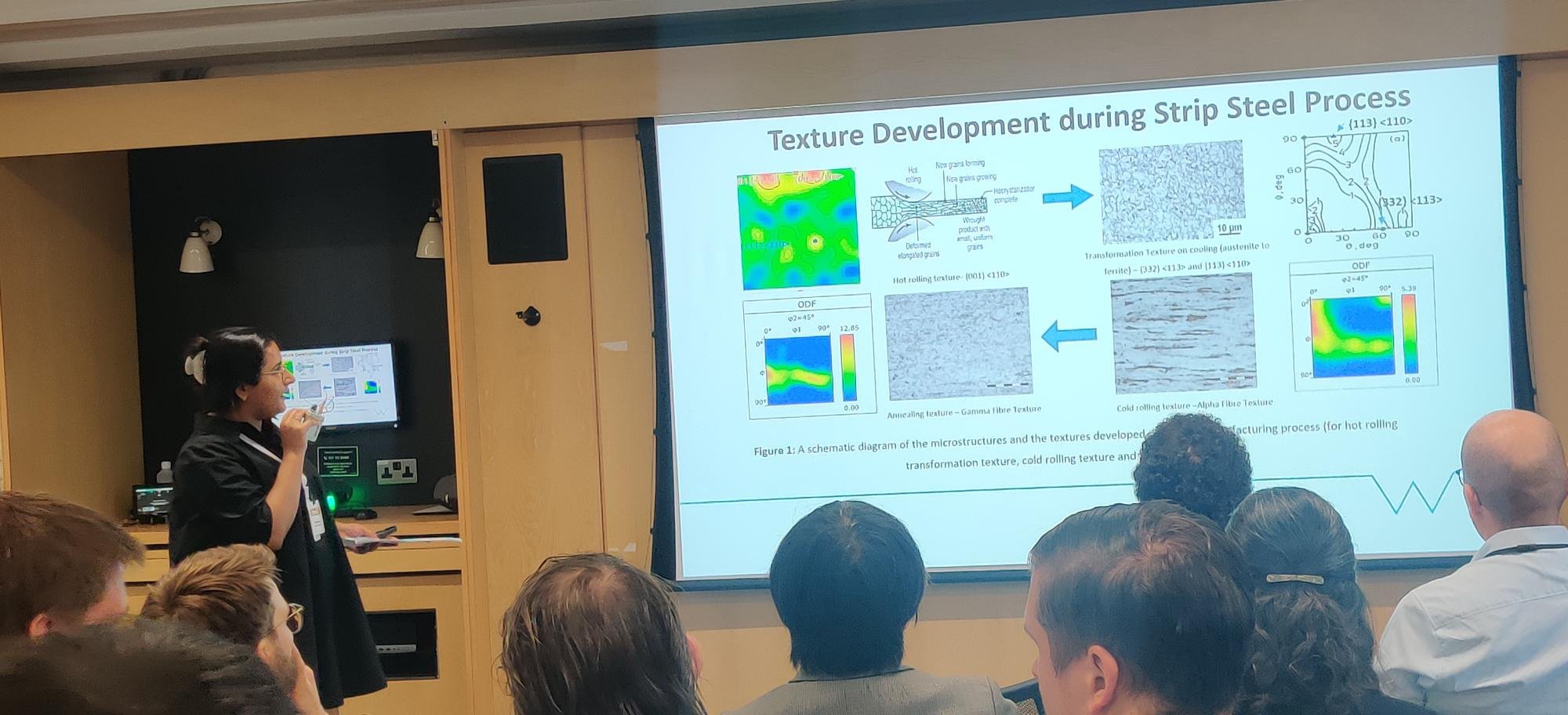

On the final day three of the conference everyone had gelled so well together nobody could’ve guessed we’d all just been introduced 48 hours prior. The parallel presentation streams continued and even more ideas were discussed in the speaker talks. I attended the rolling/forging talks and was particularly interested in the presentations on grain size control and segregation of C-Mn steel grades. The talks ranged from current steel grade models for oxidation/coatings to out of the box alloy design; for example developing segregation neutralised dual phase steel for improved formability. Other talks included feeding into data management and python-based automation of hot rolling simulations, based on a theoretical approach, which may have not been considered before. Day three fittingly ended with special mentions who all played their part in making the event possible, but one very special thanks went to the organisers, in particular Dr. Carl Slater from the steels group in WMG, for making all possible arrangements for the event to be free flowing and smoothly run to perfection.

The University of Warwick, more importantly I feel the UK, continues to boost innovation to help deliver a shared vision of a cutting edge, vibrant and sustainable steel industry. This, coupled with the massive boost of confidence from this conference, will create an environment to support a responsible, clean and smart steelmaking future in making giant strides forward.

My experience of the conference is evergreen and wonderful, the work industrialists and academics had showcased is a testimony of the capabilities we collectively have in our possession. It is clear that there are tremendous efforts being made in the ever-changing steels industry to tackle its future prospects together. We must collectively come together as a wider community and this conference was the perfect illustration of how to do it!