Smart Sensors

for Real-Time Measurement

Task 8 Team

-

Prof. Claire Davis

University of Warwick

-

Dr Lei (Frank) Zhou

University of Warwick

Introduction

Improved monitoring of steel production allows for greater digitalisation and control, leading to more efficient, less energy-intensive manufacturing. Improved monitoring of processes is a key part to sustainability, growth and modernisation for the steel industry. Significant improvements have been made for real-time monitoring and feedback control, but several areas have been highlighted where insufficient information is currently available, requiring new and improved sensing approaches. One area is microstructural monitoring during processing, and electromagnetic (EM) sensors are ideal candidates. The project focuses on the development of new EM sensors and signal-microstructure relationships for use in steel processing. The Task 8 project has included the design, build and installation of an EM sensor array into a furnace-run-out table for phase transformation monitoring during cooling. Finite element modelling and experimental validation has been carried out to link the sensor signals to magnetic properties and microstructures for specific complex geometry steel products (wire/ rod and narrow strip). In addition to the steel product focused work, the project has also included developing an improved fundamental understanding of the link between magnetic signals and steel microstructure, including changes in magnetic signals with temperature.

This benefitid the main T8 project in understanding the sensor signal – sample geometry effects. Dr Zhou also successfully obtained a SUSTAIN ECR grant (on the effect of temperature and magnetic field on domain wall movement) in Feb 2021 for 12 months at 0.5 FTE and a TFI ECR grant (on atomistic scale simulation of the magnetic anisotropy in steels) in June 2022 for 6 months at 0.5 FTE. Both ECR projects focus on some specific aspects of fundamental understanding, which align well with one of T8 aims to improve fundamental understanding of the link between magnetic signals and microstructure. These parallel funded activities allowed the overall T8 project end date to be extended providing continuity.

A new four-EM sensor head array system has been designed, built and installed in the lab furnace-roller table at WMG, University of Warwick. The sensor array finite element model has been developed and validated for samples with known magnetic properties. This allows the EM sensor signal to be correlated to the magnetic properties, and hence microstructures, for specific complex geometry steel products (wire/rod and narrow strip). The results to date have identified a suitable sensor array design to allow improved spatial resolution of the signals.

A high-temperature cylindrical shaped EM sensor was used to demonstrate the capability of the EM sensor approach to monitor recovery and recrystallisation for IF steel in-situ during annealing heat treatment. The results provided proof of concept for in-situ measurements at high temperatures and supported new project proposals.

Through the ECR project, in-situ magnetic domain observation using Lorentz microscopy in the TEM with a high-temperature sample holder has been completed showing domain movement under changing magnetic fields and temperature. It was found that both increasing magnetic field and temperature allows magnetic domain walls to overcome pinning features. This is the first time both temperature and magnetic field effects on domain wall movement has been observed for structural steel grades and supports understanding for the effects of temperature.

High temperature magnetic property measurements were carried out using a high-temperature Epstein frame setup, for full BH behaviours. The work was carried out with the University of Manchester and is part of an on-going collaboration for EM sensor developments. The measured results will be used in models for sensor-microstructure transformation monitoring and to examine effects of microstructural parameters.

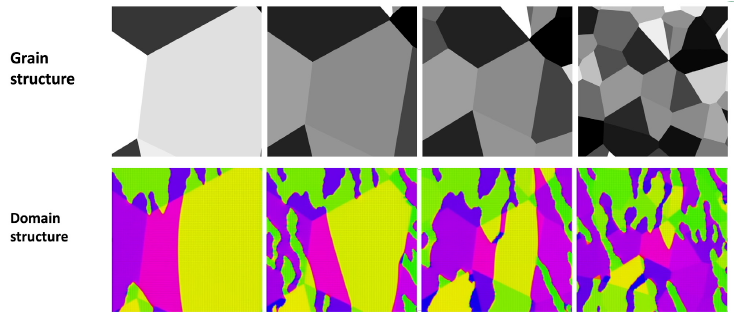

Figure 1: Micromagnetic modelling. 2D model around 16x16 μm with grain sizes of 3, 6, 9 and 12 μm modelled. The effect of applied magnetic field on domain structures was modelled on steel samples with different grain size.

Outcomes

The project has extended the fundamental understanding of the relationship between magnetic signals, steel microstructure and temperature, as well as translation to industrial exploitation for EM sensor systems.

Work has been carried out on the development a new EM sensor array system designed to measure steel grades with more complex geometries than previous work, which focused on sensors for wide strip steels. The new array system builds upon knowledge gained through earlier collaborative efforts with the University of Manchester, Primetals Technology Limited, and Tata Steel on the now commercial EMspec system. The four-sensor head approach in the array required detailed modelling to optimise the design and minimise interference between the sensor heads. The modelling stage progressed successfully, leading to a proposed design that was contracted for the build phase. The new hardware was received and installed in a laboratory furnace-roller table for trials, followed by validation of the modelling tests. Additional funding through a High-Value Manufacturing (HVM) Catapult-funded project has meant that two EM sensor array systems have been manufactured to be installed at Liberty Steel (narrow strip mill) and British Steel (rod mill) in Spring 2025. The installation will provide real-world testing in an operational steel mill environment for the prototype sensor array and generate significant industrial data, which will be assessed within the project for in-situ real time phase transformation assessment.

Studies have been carried out on the effect of temperature on the magnetic properties of steels, using a novel high temperature Epstein Frame, designed by the University of Manchester for full BH properties, and Lorentz microscopy in a TEM with high temperature stage. BH curves at room and high temperatures for steels with different grain sizes have been measured and it has been identified that both increasing temperature and increasing magnetic field strength allow domain walls to overcome pinning sites. These studies align with Task 8’s broader aim of improving the fundamental understanding of the relationship between magnetic signals and microstructural features. The continued research effort strengthens the project’s potential for industrial adoption and future applications in steel production / property monitoring.

A new four-EM sensor head array system has been designed, built, and installed in the lab furnace-roller table at WMG, University of Warwick. The sensor array finite element model has been developed and validated against samples with known magnetic properties. This enables the EM sensor signal to be correlated to the magnetic properties, and consequently, the phase transformation state for specific complex geometry steel products, such as wire/rod and narrow strip. The results to date have identified a suitable sensor array design that improves the spatial resolution of the signals. In parallel, through a High-Value Manufacturing (HVM) Catapult-funded project new EM sensor array systems have been fabricated and incorporated into run out table design constraints for installation at Liberty Steel and British Steel, with deployment expected in the spring of 2025. This is a crucial step towards transitioning from laboratory validation to real-world application in steel mills, facilitating the industrial implementation of the designed sensor array within Task 8.

High-temperature laboratory cylindrical EM sensor tests have been used to quantitatively relate EM signals to recovery and recrystallisation for IF steel in situ during annealing heat treatment. Additionally, the sensor has been used to monitor spheroidization in pearlitic steels and tempering in martensitic steels. The results have provided proof of concept for high-temperature in-situ measurements for microstructural changes in steel. Challenges include the design of sensors that can withstand prolonged exposure to high temperatures and sensor signal interpretation, which are now being tackled in a parallel EPSRC project with the University of Manchester.

High-temperature magnetic property measurements were conducted using a high-temperature Epstein frame setup to capture full BH behaviours. This work, undertaken in collaboration with the University of Manchester, is part of ongoing research into EM signal -microstructure interpretation and sensor development, which is supported by fundamental observations on magnetic domain wall movement. It was found that increasing both magnetic field and temperature enables domain walls to overcome pinning features, which marks the first time both temperature and magnetic field effects on domain wall movement have been observed for structural steel grades and contributes to the understanding of temperature effects on magnetic behaviour.

Impact

Commercial electromagnetic sensor systems are well-established for cold-strip mill applications, where signals are correlated to final mechanical properties. The only commercial system currently available for hot-strip steel microstructural monitoring remains the EMspec system, developed by Primetals Technology Ltd. Recently, four EMspec sensors have been installed along the run out table in the hot-strip mill at Tata Steel Port Talbot. On-going work is determining sensitivity of signals to operation parameters and steel grade transformation prediction.

There is increasing demand and interest in extending the application of EM sensor technology beyond strip steel to encompass more complex geometries and a broader range of steel grades. The development of the EM sensor array prototype system marks a significant advancement in this direction. Following successful design development and laboratory-scale testing, prototype EM sensor arrays have been developed and are now ready for industrial trials at Liberty Steel and British Steel.

The proof-of-concept study for in-situ high-temperature microstructural monitoring—including IF steel recovery and recrystallisation, as well as tempering and spheroidization—has further validated the potential of using an approach for microstructural assessment in demanding industrial conditions. This progress has led to additional funding through an EPSRC Instrumentation Grant to further develop high-temperature sensor systems in collaboration with the University of Manchester. These advanced sensors are currently undergoing testing for laboratory research applications and potential industrial deployment in annealing furnaces and other heat treatment processes.

With these developments, the project is well-positioned to deliver substantial industrial and academic impact, supporting the advancement of EM sensor technology for steel microstructure monitoring across a broader range of steel products and processing conditions.

Next Steps

The prototype of the newly developed sensor array, based on the design and development work through Task 8, has been made, tested and is now prepared for installation in industrial mills. Additionally, four EMspec sensors developed by Primetals Technology has been successfully installed at Tata Steel Port Talbot. For both applications, industrial sensor data and processing parameters are becoming available. A significant effort is now required to analyse this data and enhance the interpretation of EM sensor signals in an industrial environment to improve accuracy and reliability.

In terms of the fundamental scientific study on the effect of temperature and microstructural parameters on the full magnetic behaviour of steel, a combined modelling and experimental approach remains essential. Further funding is being applied for to develop this understanding, which is required to underpin future exploitation for complex microstructure assessment. Feasibility funding has been secured to explore the combination of ultrasonic and electromagnetic sensor data analysis for high-temperature microstructure monitoring. This study will assess the potential for integrating multiple sensing modalities to enhance real-time microstructural assessment under high-temperature conditions, bridging gaps in current sensor capabilities.

With these advancements, the project is progressing both real-world industrial deployment and fundamental knowledge, ensuring both practical applications and deeper scientific understanding of EM sensor technology in steel processing.