Thermal Efficiency

Task 6 Team

-

Prof. Cameron Pleydell-Pearce

Swansea University

-

Dr Jon Elvins

Swansa University

-

Nicola Thomas

Swansea University

-

Geraint Howells

Swansea University

-

Nigel Koungampillil

Swansea University

Introduction

According to the International Energy Agency (IEA), heating accounts for 66% of industrial energy demand, which itself makes up 20% of total energy demand. Steel production represents a significant proportion of that demand and as there are some fundamental thermodynamic limitations to consider, such as iron’s melting point (15380C) and its key solid state phase transformation temperatures (e.g. ɣ > ɑ at 9200C). Currently, a typical UK integrated plant loses 20PJ/yr through the largest heat vector. Task 6 of SUSTAIN looks to minimise loss through improved insulation, more efficient heat transfer and two key thermal energy harvesting technologies (fig. 1).

Figure 1: The approach to targeting thermal efficiency in steelmaking within Task 6 of SUSTAIN, addressing both demand reduction and utilization of waste heat (top left to bottom right: thermal image of refractory ladle (courtesy of J. Wilmott Sheffield University), gas fired burner and reheated steel slab, casting a novel thermo-electric generator, non-toxic earth abundant thermochemical storage medium).

Project Aims

Develop as multiscale ex-situ structural characterisation approach for refractories.

Improve understanding of structure-property relations in carbon bonded refractories.

Develop robust, cost effective Sn-Se thermoelectric materials / devices for integration into refractory linings.

Build UK academic skill base in the field of refractories.

Improve steel re-heating efficiency.

Develop robust, energy efficient thermochemical heat storage materials suitable for steel production

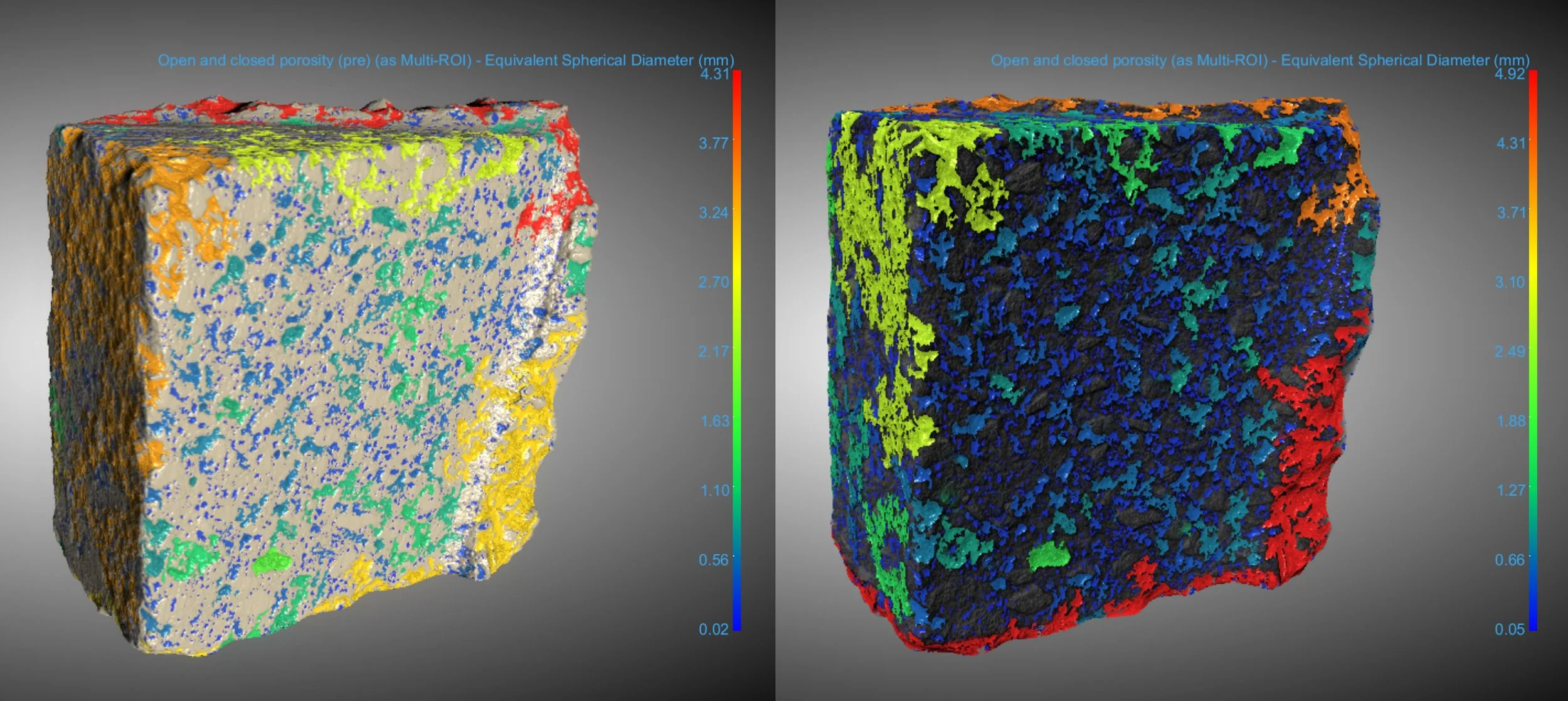

Advanced correlative microscopy and porosity analysis to assess the effects of H-DRI on refractories

Decarbonisation of steelmaking is moving towards using hydrogen for direct reduced iron processes. Hydrogen has been found to negatively interact with some materials including refractories, particularly those containing silica. Research is currently being conducted using correlative microscopy including X-ray micro-computed tomography (XCT), scanning electron microscopy (SEM) including energy-dispersive X-ray spectroscopy (EDS) mapping, and optical microscopy. Samples of two types of refractories were selected and treated in a horizontal furnace using hydrogen gas at a temperature of 1050°C for 150 hours. Materials characterisation and correlative analysis techniques including porosity analysis of the samples have been used to compare the materials pre and post hydrogen treatment. Results show changes in porosity and volume have occurred. Further work in this area is in progress to investigate the effect of increased time in the hydrogen furnace.

Development of Refractory Systems to Support the Steelmaking Process

Several industrial plant trials were undertaken to better understand the in-service performance of refractory linings and to identify areas in which these may be improved to aid energy conservation efforts.

These trials focused on the insulating covers, referred to as lids, which are used to retain and conserve heat within the steel ladles during the steelmaking and casting process. The nature of these lids being mobile assets that routinely experience temperatures in excess of 1000°C, coupled with the need for safe access and egress in a live steel plant, posed a number of challenges when collecting accurate thermal data using installed thermocouples.

These challenges were overcome by using LoRa WAN technology to send the temperature data from the lid wirelessly to a recording computer, with additional support from non-contact infra-red thermal imaging. The collected data has been used to help validate a 3D FEM model of a caster lid to allow for optimisation of the design and refractory selection.

With the success of the steel plant trials, the use of LoRa WAN transmitters has been expanded to include a trial currently underway at the hot mill reheat furnaces. Here an assessment of a newly installed, more insulative refractory lining configuration is being conducted as part of a project to improve energy efficiency.

Utilisation of industrial waste heat

Fundamental analysis for this period has been split between sizing the opportunity, i.e. categorising the building types, average building thermal load and ascertaining the number of buildings per building type (Schools, Offices etc…) and refining the decarbonisation impact calculations with respect to transport opportunity. Combining this input with data from sister projects, a fundamental model is being enhanced to size the decarbonisation and economic opportunity at local, regional and national levels, based on available waste heat data, local schemes tracking building energy consumption and energy performance certificates available.

Further concept demonstration projects have been sought, and a waste stream evaluation is ongoing with Sheffield Forgemasters. Focused upon the waste heat from the foundries, initial assessment of supplied data has been completed, and a continuous monitoring programme is now being instigated to provide a refined figure for the waste heat harvesting potential of this site.

Continuous Temperature Measurement of Liquid Metal

The physical modelling of Argon injection in molten steel, subjected to machine learning, has provided quantitative insights into plume interaction and stirring efficiency. The study linked plume volume to flow rate and tuyere slot placements, revealing critical behaviour patterns and refractory wear caused by thermo-mechanical stresses. Analysis of plume aspect ratios facilitated understanding of shape factors and emissivity, enabling online temperature measurements.

A VOF (Volume of Fluid) model was developed to examine thermodynamic interactions, validated by matching temperature fluctuation frequencies with physical model data. This model now aids in analysing turbulent viscosity and velocity profiles within the melt.

Significantly, this research secured MPI Industrial Scale-Up funding, underscoring the project's impact and potential. This funding accelerates ongoing work on a lance design, integrating experimental data and industrial insights to enable online measurements within the melt.